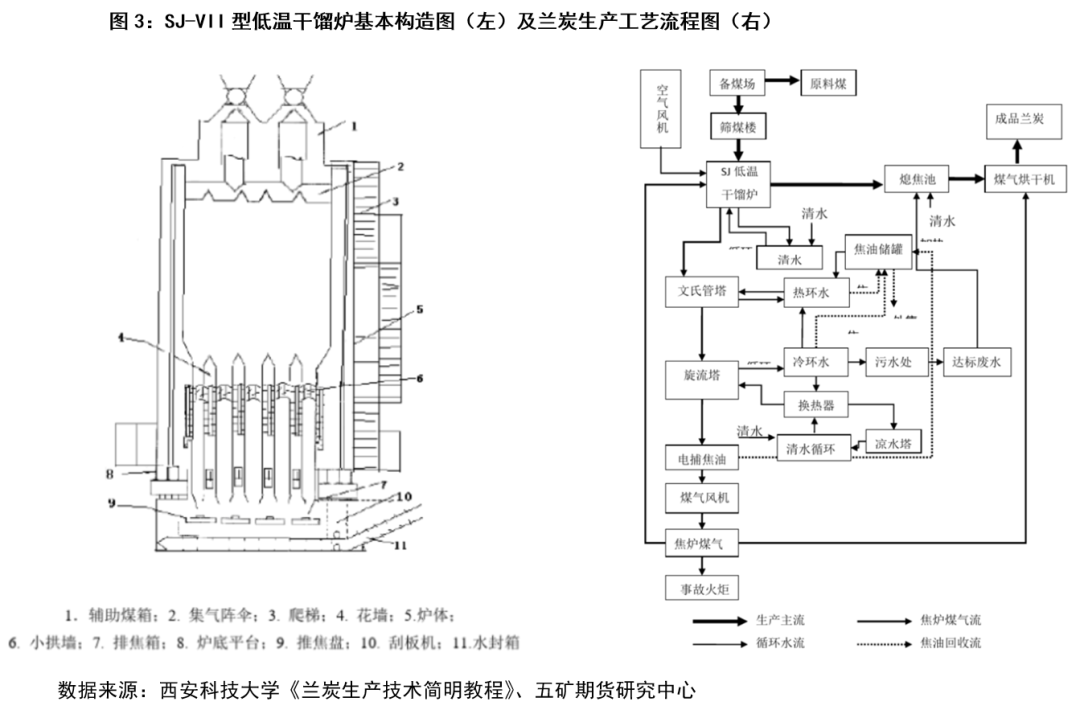

The production of orchid carbon is mainly based on low temperature retorting (that is, the process of coal pyrolysis under the condition of isolation of air), and the temperature of retorting is generally controlled between 600℃ and 750℃. In the process of producing charcoal, coal gas and coal tar are also produced as byproducts. The production of orchid coal mainly uses long flame coal, non-cohesive coal, weak cohesive coal and other non-cohesive or weak cohesive coal, high volatile bituminous coal.

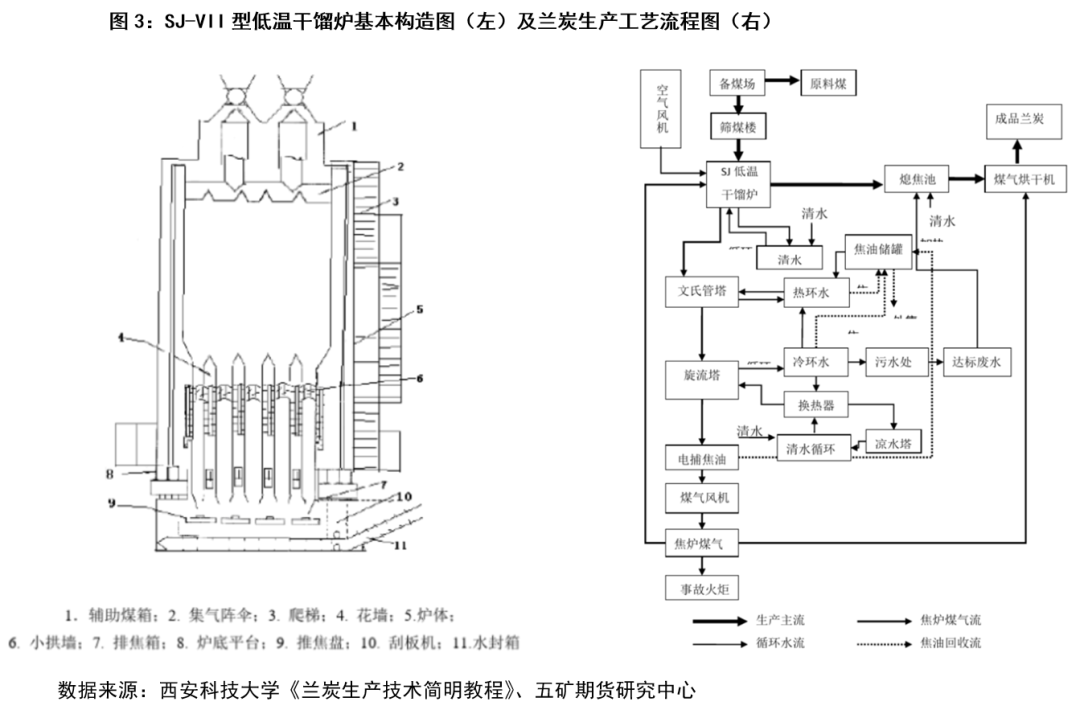

Traditional charcoal furnace includes external heat type and internal heat type. The external heat type uses the way of fire channel heating, the furnace is complex, the thermal efficiency is low, the investment is about three times of the internal heat type. The internal thermal charcoal furnace mainly includes the upright three-stage furnace developed by Anshan Thermal Energy Institute, Shaanxi Metallurgical Design Institute and Shenmu Sanjiang, among which the single furnace capacity of Shenmu Sanjiang's SJ-V charcoal furnace has reached 200,000 tons/year, and the lower limit of the size of raw coal is 3mm. (China Ferroalloy net)

At present, the main coal furnace used in the market is vertical three-stage furnace (internal heat type), and SJ low temperature retort is the main furnace. The orchid carbon device is mainly composed of coal preparation section, carbonization section, screening section, gas purification section and other parts.